The Importance of Aluminum Foundry in Progressing Industrial Production Techniques

The Aluminum Foundry plays an essential role in the development of commercial production methods. Its light-weight residential properties and adaptability make Aluminum a perfect selection for various applications. Advanced casting methods, consisting of die spreading and 3D printing, allow for elaborate styles and mass production. As the market moves in the direction of automation and sustainability, questions develop concerning the future trajectory of Aluminum foundries and their influence on manufacturing effectiveness. What obstacles and innovations lie in advance?

The Function of Aluminum in Modern Production

Aluminum plays a crucial duty in modern manufacturing due to its distinct properties and flexibility. As a lightweight steel, it notably reduces the overall weight of products, improving fuel effectiveness in transportation and aerospace markets. Its superb deterioration resistance warranties long life and integrity, making it excellent for numerous applications, from vehicle elements to developing products. Aluminum's malleability allows it to be conveniently formed right into complicated designs, facilitating cutting-edge item advancement. Its conductivity makes it ideal for electric applications, contributing to advancements in electronic devices and sustainable power technologies. The flexibility of Aluminum additionally encompasses its recyclability, which adds to lasting manufacturing techniques. As markets continue to focus on performance and environmental responsibility, Aluminum stays a crucial product, promoting development and boosting production procedures across numerous industries. Its role is not simply functional; it is fundamental to the evolution of modern-day commercial practices.

Trick Advantages of Aluminum Spreading

The advantages of Aluminum casting are substantial, adding to its appeal in various commercial applications. One key advantage is the light-weight nature of aluminum, which lowers transportation expenses and boosts fuel effectiveness in automotive and aerospace fields. Additionally, light weight aluminum's excellent rust resistance expands the lifespan of actors components, making them excellent for aquatic and exterior environments.

On top of that, Aluminum spreading enables intricate geometries and intricate designs, supplying suppliers with greater flexibility in product advancement - Aluminum Castings. The material likewise displays great thermal and electric conductivity, making it ideal for a variety of digital applications

Another advantage is the rapid solidification process, which results in finer microstructures and enhanced mechanical buildings. Aluminum can be reused repetitively without shedding its intrinsic top qualities, advertising sustainability in manufacturing practices. These benefits emphasize Aluminum spreading's essential function in advancing industrial manufacturing strategies while satisfying diverse engineering needs.

Cutting-edge Casting Techniques and Technologies

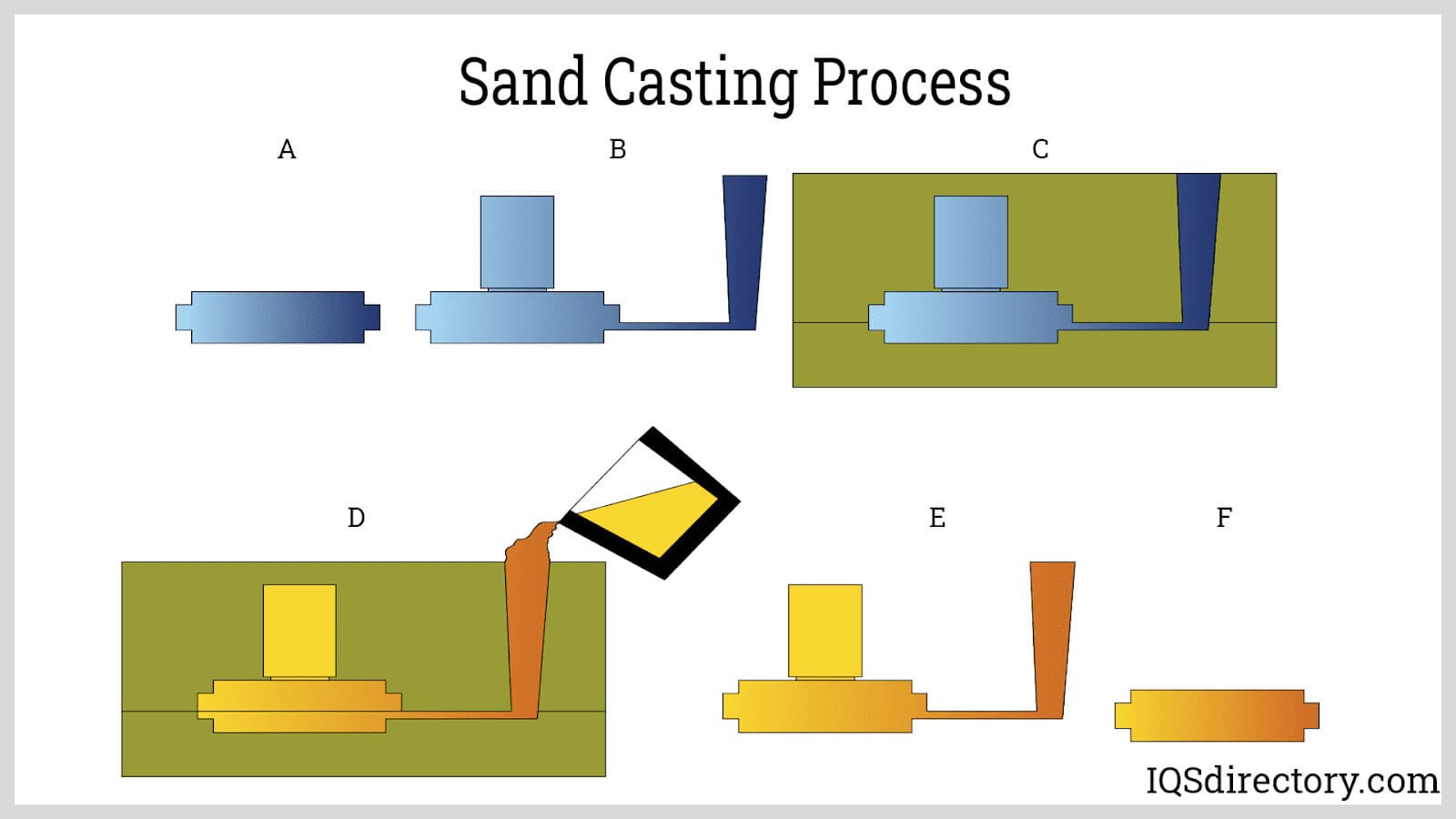

Numerous cutting-edge casting techniques and technologies have actually arised to improve the efficiency and quality of Aluminum manufacturing. Among these, die spreading attracts attention as a technique that enables high-volume production of intricate shapes with excellent dimensional precision. This method utilizes high stress to inject liquified Aluminum right into a mold, causing smooth surfaces and reduced demand for machining.

One more notable innovation is making use of 3D printing for molds, which allows rapid prototyping and lowers lead times considerably. This innovation permits detailed layouts that standard methods might struggle to accomplish.

Additionally, financial investment casting proceeds to evolve, making use of advanced products and processes to produce accuracy components. The fostering of computer system simulations in the casting procedure has even more boosted outcomes by forecasting potential problems and maximizing mold and mildew designs. Together, these technologies are transforming Aluminum shops, paving the method for extra efficient production and premium product high quality in various markets.

Environmental Effect and Sustainability in Aluminum Foundries

As sectors increasingly focus on sustainability, the environmental effect of Aluminum foundries has come under scrutiny. These centers are considerable factors to greenhouse gas discharges and energy consumption, largely as a result of the energy-intensive procedures associated with melting and casting aluminum. The extraction of bauxite, the key ore, more exacerbates ecological problems, causing habitat destruction and pollution.

In response to these difficulties, many Aluminum factories are taking on extra lasting practices (Metal Castings). Innovations such as recycling scrap Aluminum significantly decrease power use and exhausts, as reusing requires only a portion of the power needed for main production. Furthermore, the assimilation of renewable resource resources, such as solar and wind power, is getting traction in factories aiming to decrease their carbon footprint

Additionally, advancements in modern technologies that decrease waste and improve source effectiveness are ending up being vital for the future of the Aluminum market. These initiatives highlight the shift in the direction of a much more sustainable and ecologically accountable method in Aluminum factories.

Applications of Aluminum Casting Across Industries

Aluminum spreading locates widespread application throughout diverse industries, owing to its beneficial residential properties such as lightweight, deterioration resistance, and excellent machinability. In the automotive field, makers use Aluminum spreadings for engine components, transmission real estates, and structural parts, improving gas efficiency and performance. The aerospace sector take advantage of aluminum's strength-to-weight ratio, utilizing it in airplane frames and elements, which add to reduced total weight and enhanced fuel economy.

The consumer electronics market uses Aluminum castings for housings and chassis, incorporating visual appeal with sturdiness. In construction, Aluminum castings are utilized for home window structures, doors, and building elements, offering both performance and layout adaptability. In addition, the marine industry utilizes Aluminum casting for boat hulls and fittings, making sure resistance to deep sea deterioration. This hop over to these guys versatility across numerous areas emphasizes Aluminum casting's vital role in contemporary commercial applications, driving advancement and performance.

Obstacles Faced by Aluminum Foundries

Aluminum foundries encounter significant challenges in meeting stringent ecological laws while keeping functional performance. Furthermore, a lack of knowledgeable labor aggravates these troubles, impeding efficiency and development. Dealing with these issues is essential for the sustainability and development of the Aluminum spreading market.

Ecological Laws Compliance

Light weight aluminum foundries play a necessary role in commercial production, they usually deal with substantial difficulties in abiding with environmental laws. These policies are made to reduce air and water air pollution, waste generation, and energy usage. Shops usually must purchase innovative innovations to fulfill stringent discharge criteria and manage harmful products efficiently. The expenses related to these upgrades can strain economic sources, particularly for smaller procedures. In addition, the complexity of passing through governing structures can lead to compliance errors, causing pricey penalties. Constant adjustments in laws call for shops to adapt swiftly, frequently requiring continuous training and updates in functional techniques. Stabilizing governing conformity with manufacturing performance continues to be an essential problem for the Aluminum Foundry sector.

Skilled Labor Shortage

As the Aluminum Foundry industry remains to develop, a pressing difficulty has emerged: a skilled labor shortage that threatens the field's performance and development. This lack is mainly fueled by an aging workforce and the absence of passion amongst younger generations in pursuing careers in production. Lots of proficient tasks need customized training and experience, which are significantly tough to locate. Subsequently, Aluminum shops struggle to maintain functional performance, leading to hold-ups and raised manufacturing prices. Initiatives to attract brand-new ability with apprenticeship programs and partnerships with instructional organizations are underway, yet these initiatives take some time to yield outcomes. Without a robust increase of experienced employees, the Aluminum Foundry market might face substantial difficulties in fulfilling the demands of modern-day industrial manufacturing.

Future Trends in Aluminum Foundry Manufacturing Techniques

The future of Aluminum Foundry manufacturing methods is positioned to be substantially formed by developments in automation and lasting product developments. Automation is expected to boost efficiency and accuracy in Foundry procedures, decreasing labor prices and minimizing human mistake (Metal Castings). At the same time, a growing emphasis on sustainability will certainly drive the development of green materials and methods, straightening the industry with worldwide ecological objectives

Automation in Foundry Processes

Lasting Material Innovations

While the Aluminum Foundry industry accepts automation, a parallel concentrate on sustainable product advancements is reshaping manufacturing methods for the future. Developments in reusing procedures are allowing foundries to make use of post-consumer light weight aluminum, markedly lowering power consumption and waste. The development of green additives and layers is lessening the ecological effect linked with traditional materials. Technologies in lightweight Aluminum alloys are improving efficiency while promoting sustainability, making products not only extra efficient however additionally simpler click here to read to recycle at the end of their life process. As the sector adapts to stricter environmental guidelines, these lasting techniques are becoming vital. Inevitably, the dedication to sustainable material developments in Aluminum factories will certainly drive boosted productivity while dealing with worldwide environmental difficulties.

Often Asked Inquiries

Just How Does Aluminum Contrast to Various Other Steels in Casting?

Aluminum offers advantages over other steels in spreading, consisting of reduced melting points, exceptional fluidness, and resistance to deterioration. These residential properties make it possible view website for detailed layouts and faster manufacturing, making Aluminum a recommended selection for several sectors.

What Precaution Are in Area in Aluminum Foundries?

Precaution in Aluminum shops consist of safety gear for workers, proper ventilation systems, normal tools upkeep, fire prevention protocols, and strict adherence to safety and security laws, making certain a safe and secure setting while decreasing the threat of crashes and injuries.

Just How Are Aluminum Alloys Selected for Details Applications?

Aluminum alloys are picked based upon mechanical properties, rust resistance, and thermal conductivity. Designers review application needs, taking into consideration aspects like weight, stamina, and environmental problems, making sure optimal performance for details industrial or commercial usages.

What Is the Average Life-span of Aluminum Cast Products?

The typical lifespan of Aluminum actors products commonly ranges from 20 to half a century, depending upon environmental aspects, usage problems, and maintenance techniques. Proper treatment can significantly expand their functional long life and performance efficiency.

Exist Certifications for Aluminum Foundry Processes?

Yes, there are accreditations for Aluminum Foundry procedures, including ISO 9001 for high quality monitoring systems and particular market criteria like ASTM and SAE, which guarantee adherence to high quality and safety and security in Aluminum manufacturing and casting.

Aluminum factories play a crucial role in industrial manufacturing, they usually face considerable difficulties in abiding with environmental policies. Aluminum factories battle to maintain operational efficiency, leading to delays and boosted manufacturing prices. The future of Aluminum Foundry manufacturing techniques is poised to be considerably shaped by improvements in automation and lasting product technologies. Significantly, automation is forming the landscape of Aluminum Foundry manufacturing techniques, driving efficiency and precision. While the Aluminum Foundry market welcomes automation, a parallel focus on lasting material technologies is reshaping manufacturing strategies for the future.